Ethylene Oxide (EtO) Sterilization Process

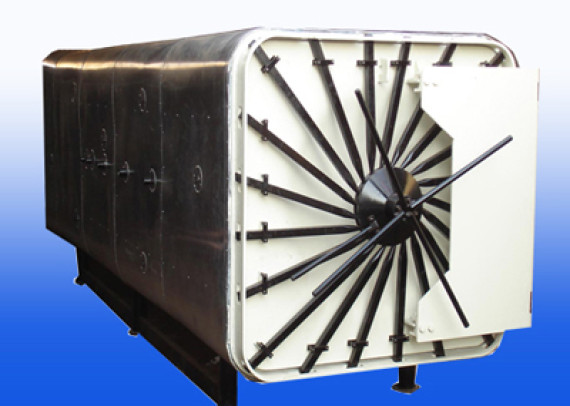

Ethylene Oxide (EtO) sterilization is mainly used to sterilize medical and pharmaceutical products that cannot support conventional high temperature steam sterilization - such as devices that incorporate electronic components, plastic packaging or plastic containers.

EtO gas infiltrates packages as well as products themselves to kill micro organisms that are left during production or packaging processes. This gas, mixed with air at a ratio of at least 3% EtO gas, forms an explosive mixture. Pure EtO gas boiling point is 10.73 ºC at atmospheric pressure. Most of the time, it is mixed with Nitrogen or CO2. This explosive condition requires Intrinsic Safe material (ATEX) zoning, for security of people as well as security of the process itself.

Safety of personnel is an important issue due to the harmful effect of EtO on humans. Polluted areas need to be alarmed using gas detectors set up at different locations to monitor any leak. Visual and audio alarm systems need to be provided. The system must inform any operator when a sterilization cell contains EtO.

When this toxic gas is removed from the room it needs to be treated using thermal burners, scrubbers or oxidation for environmental protection or be transported to an alternate facility for treatment.